DELTA NEWS - DECEMBER 2018

In This Issue...

News

- Analyzing a Hydraulic System Performance

- Closed-Loop Control Enables Precise Press Operation

- Motion Control for a Heavy-Duty Test Stand

- Multi-Axis Motion Controller Accelerates Gear Testing

Further Reading

Product News

- RMC200 Receives PROFINET Certification

- Prewired Cables Available for RMC200 Modules

Distributor Highlight

People at Delta

- Wade Nylund - Project & Quality Management

Trade Shows

& Conferences

Learning More About Delta

|

|

|

|

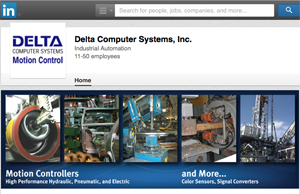

Analyzing a Hydraulic System Performance: If You Can Study

It, You Can Improve It

|

To improve how a hydraulic system

works, including reducing the amount

of energy it consumes, you need to

record and analyze data on how it

currently operates and analyze it.

That’s what Luis Javier Berné of

IhBER S.L. of Zaragoza, Spain is doing.

IhBER designs hydraulic systems

and distributes hydraulic system

components. The company previously

developed the designs for all of the

hydraulic controls of a

side-loader refuse truck, including the

control system that powers the

lifting arm. Though the system works

fine, IhBER engineer Berné has

been analyzing its operation to see if

it could be improved. Berné’s

work played a large role in his studies

leading to a Ph.D. at

Universitat Politécnica de Catalunya,

LABSON Fluid Power Laboratory, in

Terrassa (Barcelona), Spain.

(FluidPower Journal, October 8th, 2018)

|

|

|

|

|

|

|

|

|

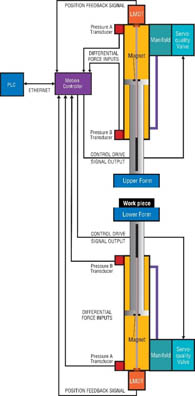

Closed-Loop Control Enables Precise Press Operation

|

For many press applications, precise,

coordinated motion holds the key to

maximizing productivity

and minimizing waste and maintenance costs.

Whether working on a new press or

retrofitting a control

system to an old press, success often rides

on the capabilities of the motion

controller. Here, using

a hydraulic press as an example, the

controller ensures operational

repeatability–achieving tight

control of ram speed and force applied. In

turn, this necessitates using the right

transducers and valves,

and a motion controller with closed-loop

control and fast cycle time.

Successful pressroom performance, in many

cases, hinges on the motion controller's

ability to accurately

synchronize the motion of multiple

axes–critical when the job requires a level

platen as multiple

compression rams operate, or on presses

that form parts between two active

hydraulic actuators.

(MetalForming, November, 2018)

|

|

|

|

|

|

|

|

|

|

|

|

Motion Control for a Heavy Duty Test Stand

|

NTS Corp., headquartered in Anaheim,

California, offers testing, inspection, and

certification projects

for many industries, including aerospace,

defense, automotive, and consumer markets.

“We have well over 150 different tests going

on at the same time at our 125-acre

Huntsville, Alabama, location alone,”

says Jim Birkholz, NTS Huntsville design

engineer.

The

Huntsville facility uses some large-scale

test systems. For example,

one test stand developed by NTS, a swing

table, weighs about 17,000 lb

and has been designed to test naval and

aerospace assemblies weighing

up to 50,000 lb. The system has been used

for testing the integrity of

helicopter fuel tanks and for testing jet

engines.

(Aerospace Manufacturing & Design,

November/December, 2018)

|

|

|

|

|

|

|

|

|

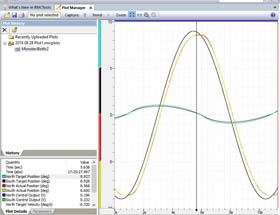

Multi-Axis Motion Controller Accelerates Gear Testing

|

|

Materials testing and characterization

is often a lengthy process. It can take

more than a year and billions

of testing cycles for a manufacturer to

characterize the properties of a new

metal compound to be used in a

critical application such as a

component of an automotive or jet

engine.

Typically, the testing regimen is

prescribed by an OEM in accordance with

procedures specified in industry

organization standards; for example,

one testing method for bending fatigue

of gear steels is outlined in SAE

Standard 1619 using a standard fixture

and standard gear design. Companies

manufacturing automotive and aerospace

engines often refer to this and other

standards as they specify the materials

and designs of gears to be used in

their applications, as do companies

manufacturing test systems that verify

production gears meet the standards.

(Tech Briefs, December 1, 2018)

|

|

|

|

|

|

|

|

|

Product News

RMC200 Receives PROFINET Certification

Delta Computer Systems, Inc. is pleased

to announce that

PI has certified the RMC200 as a

PROFINET IO device. Delta is

committed to ongoing development and

support for a wide variety of

industrial communications protocols,

ensuring our customers have the

benefits of fast, precise

servo-hydraulic and servo-electric

control.

With the next firmware release (early Q1 2019) the

RMC200 will join the RMC150 and the

RMC75 as PROFINET communications

certified devices.

Prewired

Cables Available for RMC200 Modules

Delta Computer Systems now offers

prewired cables for the RMC200 to speed

installation.

These compact cables provide a convenient

option for short runs within a cabinet from

the RMC200 I/O modules to terminal blocks.

These six foot long cables (standard length)

are prewired to a terminal block on the module

side, running to pigtailed ends for user connection

flexibility.

Distributor Highlight

IhBER S.L.

IhBER S.L. is a full-service hydraulic

distributor located in Zaragoza,

Spain. Founded in 1984, IhBER provides

experienced design services,

skilled installation and commissioning, and

responsive technical

support and system maintenance services.

IhBER distributes a full line

of servo-quality valves and position

sensors along with the RMC Motion

Controllers, providing a complete precision

system solution.

IhBER designs and builds innovative

hydraulic power units (HPUs) for a variety

of industries and

applications. Energy efficiency is a

particular area of interest, and IhBER's

engineers have designed and

built HPUs that change power consumption to

match the required output, but will shut

down one or

more motors automatically when the oil

demand drops. Delta congratulates IhBER for

35 years of business.

Visit IhBER

People at DELTA

Wade Nylund – Project & Quality

Management

Delta Computer Systems is pleased to welcome

Wade Nylund to our team. Wade brings

a wealth of experience in manufacturing

engineering from several large consumer

electronics companies, qualifying and

training vendors.

One of his first projects at Delta was

managing the design of packaging for

Delta's RMC200

Motion Controller.

Wade is a Washington State native, and

enjoys hiking, fishing, and skiing

with his family in the beautiful mountains

of the Pacific Northwest.

See

Press Release

|

|

|

|

Education / Training

|

|

|

RMCTools Technical Training

Feb 12 - Feb 13, 2019

Apr 9 - Apr 10, 2019

Jun 11 - Jun 12, 2019

|

|

RMCTools Technical Training

Jan 29 - Jan 30, 2019 (Battle Ground, WA)

Mar 26 - Mar 27, 2019 (Battle Ground, WA)

Jun 18 - Jun 19, 2019 (Battle Ground, WA)

|

| Sign Up |

Sign Up |

| |

|

|

Delta also provides self-paced training options, check out some

of these options:

Video

Tutorials

An easy way to get up to speed on the RMC's features with easy

to follow video guides.

Online RMCs

Try RMCTools or custom RMCLink programs when you don't

have an RMC to test with.

|

Please check the Training page frequently as new dates for

Advanced Training are added for 2019.

|

|

|

TRADESHOWS

Upcoming Trade Shows:

Please join us! See Delta

RMC products and talk with our team at the

following locations in 2019.

Industry Open Day

Industry Open Day

National Fluid Power Centre

Nottinghamsire, UK

February 20, 2019

MSOE, Kern Center

MSOE, Kern Center

Milwaukee, WI

May 13-15, 2019

Pasadena Convention Center

Pasadena Convention Center

Pasadena, CA

May 21-22, 2019

Georgia World Congress Center

Georgia World Congress Center

Atlanta, GA

June 26-27, 2019

Booth 1406

Cobo Center

Detroit, MI

October 15-17, 2019

McCormick Place

McCormick Place

Chicago, IL

November 11-14, 2019

Booth D45451

|

|

|

|

Connect with Delta on LinkedIn

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

Watch Delta on YouTubeChannel

|

|

Visit Delta's new

YouTube

channel to watch

our latest videos.

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

If you are a distributor and

need a password or user ID

email us or call Delta at

(360)-254-8688.

|

| |

|

|

|

|

|

|

|

|

|