In This Issue...

News

- Delta continues support, production, and shipping during COVID-19 outbreak

- New Introduction to Delta video

- Multi-axis motion controller synchronizes press operation

- Peter Nachtwey makes Hydraulics & Pnematics Top 10 list!

- Tim Gessner volunteers for inaugural Scottish FIRST LEGO Robotics competition

- Delta customer video - Green Valley Manufacturing

Distributor Highlight

People at Delta

- Devon Cox, Advanced Electronics Technican

Company News

- Delta European Sales Office

Tech Tip

- Smooth System Power Up/Power Down

Trade Shows & Conferences

Learning More About Delta

- Education & Training

- Useful Links

|

|

|

|

Delta continues support, production, and shipping during COVID-19 outbreak

During this unprecedented worldwide viral outbreak, we want to first wish all of our customers, distributors, and suppliers safety and good health. Although Washington State has one of the larger U.S. outbreaks of COVID-19 infection, at this time Delta is operating at normal capacity and has not experienced any disruptions in timely service or product deliveries. Our support engineers and technical salespeople are available by phone, email, or on-line. Tradeshow schedules are changing, and we will update our website regularly to reflect these changes. In-person training events, either at Delta or regionally, may need to be postponed or canceled and we will contact attendees and update schedules as this becomes clear.

As this situation evolves, we will adapt as needed. However, Delta will maintain our commitment to providing quick product deliveries and responsive, knowledgeable customer support. Please feel free to reach out to us if you have any questions.

|

|

|

|

Introduction to Delta video

We recently published this new video about Delta Computer Systems, highlighting RMC motion controllers, the RMCTools software used for communication, programming, and tuning, and the wide variety of RMC applications around the world. We hope you enjoy this updated look at Delta!

|

|

Multi-axis motion controller synchronizes press operation

"Powder compacting presses are typically used to form complex shapes from metallic, ceramic or other powdered materials that are hardened after compression via a high-temperature sintering process. In order to evenly distribute and compact the powder throughout a complex part die, multiple motion axes operating hydraulic rams, working together, may be required.

|

|

This in turn requires coordinated multi-axis motion control. A case in point involves a new powder compacting press manufactured by Gasbarre Products Inc. of Dubois, Penn. Gasbarre makes presses in a variety of sizes, capable of exerting compaction forces from 1 to 750 tons. Most of the company’s customers are suppliers to the auto, lawn and garden, hand tool, and recreational vehicle industries."

FluidPower world, February 2020

|

|

|

Peter Nachtwey Makes H&P Top 10 List!

In January, the editors at Hydraulics & Pneumatics magazine took a look at the site search statistics for 2019. Two of Delta President Peter Nachtwey's "Motion Control" features made the list of "most often-sourced articles" in 2019! Thank you to the many readers who read Peter's work each month. The article with summaries of each entry in the top 10 is found here:

Reader's Choice: Your Top 10 H&P Articles, And a Look Ahead

#1 on the list is Checking for Cylinder Cavitation Using the VCCM, first published in the September 2019 issue.

Coming in at #8 on H&P's list is Cylinder and Valve Sizing, originally published the month before in the July/August 2019 combined issue.

|

|

|

If you haven't had an opportunity to read Peter's work before, here are the "Motion Control" articles that were published in January, February, and March 2020.

|

|

Delta customer video - Green Valley Manufacturing

Green Valley Manufacturing of Mt. Zion, Illinois builds heavy-duty die transporters and handling systems for a wide variety of forming and molding applications, across a huge number of industries. These die transporters must safely handle the heavy die, but be able to precisely maneuver around the factory floor. The die transporters featured in this video use an RMC200 to synchronize four hydraulic lift axes, as well as calculate the Ackermann steering angles required for the four-wheel-drive, four-wheel-steering system.

|

|

|

Tim Gessner volunteers for inaugural Scottish FIRST LEGO Robotics National Championships

Delta's European Sales Manager, Dr. Tim Gessner, Ph.D, shared a great opportunity he had with STEM education in Scotland. Dr. Gessner was one of three judges for the robotic design element for a regional LEGO Robotics competition at Edinburgh College last December. In late February, Dr. Gessner and his wife volunteered one of their Saturdays to be part of the team of judges for the Scottish National Championships, the first time this event has been held in Scotland. The FIRST LEGO League is an outreach program of The Institute of Education and Technology (IET) to bring hands-on STEM educational experiences to students all through the United Kingdom and Ireland. Tim says that it was a great time, and he enjoyed the chance to be involved in a great educational outreach.

To find out about LEGO Leagues around the world, visit FIRST LEGO League for more information.

|

|

|

Distributor Highlight

Donald Engineering is a privately owned industrial fluid power distributor headquartered in Grand Rapids, Michigan. Donald saw an evolution during the past decade toward more automation and robotics in the industries they serve, often being marketed by major large corporations. In order to stay competitive, Donald Engineering chose to focus internally and develop a strategy to improve and expand upon their understanding of technology and their own technical ability. While maintaining their expertise in hydraulics, Donald set out to broaden their product offerings and support for industrial automation, without abandoning the strong relationships with vendors developed over the past decades.

Donald Engineering sees Delta RMC motion controllers as an essential link between traditional heavy hydraulics and current automation. Donald has broadened and deepened their knowledge of Delta’s RMCs, allowing them to address customers unique applications and opening opportunities. Donald has done this by committing to training their current staff, expanding the technical applications team, participating in co-marketing and industry expos, and by having sales representatives actively representing the appropriate products to solve a customer’s problem. Examples of recent investment include adding three multi-discipline engineers to their existing Systems staff of two, as well as hiring a dedicated marketing/market research person.

Please visit Donald Engineering’s website to learn more about the products and services they offer and how to contact them. Delta extends our thanks and congratulations for 57 years of industrial hydraulic sales and service!

|

|

|

People at Delta

Devon Cox - Advanced Electronics Technician

Delta is pleased to welcome Devon Cox to our Production team! Devon has many years of experience with component-level troubleshooting and repair. Coming to Delta is a reunion, of sorts; Devon had previously worked with David Moore, another of Delta's Advanced Electronics Technicians, in another position several years back.

Devon's hobbies seem to be an extension of his job skills - he enjoys board gaming with friends, as well as painting game miniatures. This is a testament to his steady hands and keen eye for detail! All of the Delta team extend a warm welcome to the newest member of our Production group.

|

|

|

Tech Tip

Smooth System Power Up/Power Down

by David McNichol, Applications Engineer

Here is a good suggestion if you need to power your hydraulic system up or down, while leaving your control system energized. This tip will take care of the Integral gain in your control system. This is helpful because the Integral can sometimes have unintended consequences for system motion.

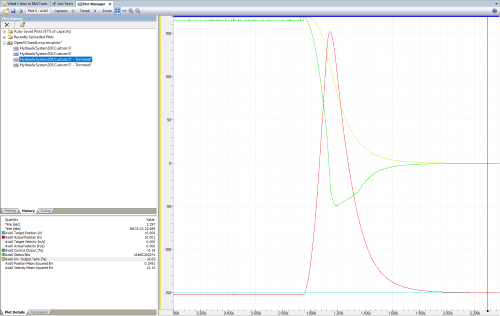

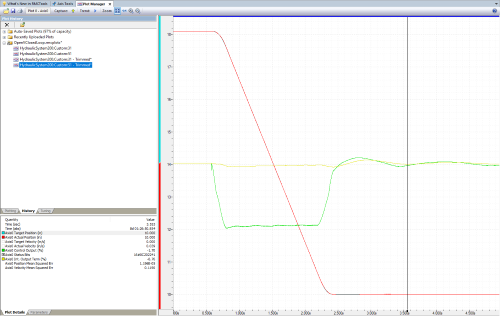

We suggest using the Stop (Open Loop) (22) command, either within your User Program or by issuing the command directly. This will ramp the output down to 0 volts at a user-specified rate, and then leave the axis or axes in open loop. The axis or axes will then be in open loop control when the hydraulics are powered back up. The plots below show why this is useful.

In the first plot, the yellow line is the Integrator Output Term, and it has caused the green Control Output to completely saturate at +10 volts. As the controller starts to control the system, the Actual Position of the axis (red line) jumps up and dramatically overshoots before coming back to the Target Position (aqua line). This would probably be undesired behavior for most systems, and could possibly lead to damage.

|

|

|

In the second plot, the Integrator Output Term (yellow) is flat, and not pushing the Control Output (green) at all. The Control Output is a negative voltage, which typically retracts the axis, as we can see by the Actual Position (red) line. The axis is now at 0 and not being commanded to move. When the hydraulic system is powered up, the axis will not jerk unexpectedly.

Delta offers a number of ways to learn more about RMCTools and RMC Motion Controller features. Delta's website has the RMCTools Online Help, which has a searchable index full of technical information. We also host the Delta Discussion Forum, where RMC users can exchange ideas on implementing applications, Applications Engineers will post code examples, and you can find recommendations from Delta's in-house testing of third-party products that work well for high-performance fluid power systems.

|

|

Tradeshows & Conferences

Upcoming Trade Shows

With the worldwide COVID-19 outbreak, the trade show outlook is frequently changing. Many shows are choosing to cancel events scheduled for early in the year; others are opting to postpone events to dates later in the year. The dates shown are tentatively scheduled at the time of publication. Please check Delta's Trade Shows page frequently for updates to our trade show schedule as they are announced.

|

|

Long Beach Convention Center

Long Beach, California

August. 10 - 12, 2020

Portland Exposition Center

Portland, Oregon

Sept. 30 - Oct. 2, 2020

Svenska Mässan

Gothenburg, Sweden

Oct. 6 - 8, 2020

The Suburban Collection Showplace

Novi, Michigan

Oct. 27 - 29, 2020

Las Vegas Convention Center

Las Vegas, Nevada

Nov. 18 - 20, 2020

|

|

|

Learning More About Delta

Education & Training

With many companies dramatically restricting travel, and many states issuing quarantine orders, including Washington, in-person classroom training is not possible at this time. Delta is addressing this by offering more of the Live Online Training sessions. The Self-Paced Learning options are not impacted in any way, and are available to interested students.

Please check Delta's Internet Training page frequently for schedule updates and added classes. You may also contact Delta by phone at (360) 254-8688, or at technicalsales@deltamotion.com.

|

|

Self-Paced Learning

Delta also offers self-paced training options, as well.

- Video Tutorials An easy way to get up to speed on the RMC's features with easy to follow video guides.

- Online RMCs Try RMCTools or custom RMCLink programs when you don't have a physical RMC to test with.

|

|

Discussion Forum

Delta's Discussion Forum is a place for users to share ideas about User Programs, unique applications, or third-party equipment that works well with the Delta RMC Motion Controllers.

|

|

Distributor Only Website

If you are a Delta distributor and need a password or user ID, email us or call Delta at (360)-254-8688.

|

|

Delta Computer Systems, Inc. © 2020 Delta Computer Systems, Inc. © 2020

1818 SE 17th St. - Battle Ground, WA USA 98604-8579

P: 360-254-8688 - F: 360-254-5435

Delta Motion Ltd.

101 Rose Street South Lane - Edinburgh, EH2 3JG, United Kingdom

P: (+44) 0131 447 7924

|

|

|

|